"SMART INTEGRATED CORROSION SYSTEM “ATLANTIC”

SICMS.SК ТU 4217-007-09890805-2013

FUNCTION

Smart Integrated Corrosion Monitoring System (SICMS) “Atlantic” is designed for distance characteristics of CPS control, optimization and adequate management of technological characteristics of cathode protection stations. The System provides with a technological process of CPS support at a good level between destructive zones of “underprotection” and “overprotrction” considering monitoring data, geological conditions in the location point of a pipeline mainlaying as well as climatic or seasonal changes.

GENERAL CHARACTERISTICS:

- An increasing module structure.

- A power-efficient network for the process of data transmission.

- An analytic data processing.

- Optimization (minimization and adaptation) of protective configuration from the point of view of the environment, communications state etc.

- Information and smart support of the process of taking decisions on the matter of management of CPS.

SOLVED PROBLEMS

- The problem of CPS protection of the objects of the pipeline systems from corrosion processes at all levels automatization.

- The process of information exchange between the users of different levels via the Internet channels network through the common interface using access data and access rights.

- Protection configuration of CPS monitoring, Corrosion Monitoring Units (CPU) set up into the MOC.SK and other means of CPS according to giving a request form.

- The process of collecting, processing, storage and displaying of CPS means monitoring results, and an inspection data, the tube state data, isolation data, corrosion ground aggressivity etc.

- Protection configurations optimization process considering monitoring data, geological conditions in the location point of a pipeline mainlaying, climatic and seasonal changes.

- The process of giving recommendations and automatic instructions CPS modes management in an on-line mode.

- In case of emergency conditions changes of CPS or an unauthorized access a warning message is given through different channels.

- The process of analytical interactive data processing, carrying out of the process of comparative and retrospective analysis to solve the problem of evaluation of the protection system of the objects of the pipeline system from corrosion.

- An ability to use a map service for displaying the objects, Cathode Protection System and the information connected with them on the map.

- The process of arranging of analytical, final and collation reports based on the system data.

- An access rights mode management to the data and system settings, keeping operational registers into the system.

- Information and smart support of the process of taking resolutions on the process of management of the means of Cathode Protection System and the system itself.

A SYSTEM’S STRUCTURE

Smart Integrated Corrosion Monitoring System (SICMS.SK)“Atlantic” is a hardware-software system.

THE FOLLOWING GENERAL RANGE OF EQUIPMENT AND MODULES CAN BE INCLUDED INTO THE SYSTEM:

- CPS-М.SК – Module Cathode Protection Station;

- SК are Distance Control and Management Units of CPS produced by other companies;

- SК are Metering Operation Centers;

- SК are Corrosion Monitoring Units, set up into Metering Operation Centers which are designed for the process of measuring of polarization and total potentials and transmitting data through the power-efficient line LPWAN. CMU.SК installation process is provided for all the Pipeline track within MOC.SК;

- SК are Corrosion Monitoring and Management Units set up into Metering Operation Centers together with PPU.SK-GrP are designed for carrying out the process of monitoring and management as well as measuring of total potential and transmitting data through the power-efficient line LPWAN;

- SК-1 are Corrosion Monitoring and Management Units set up into Metering Operation Centers together with PPU.SK-Gr are designed for carrying out the process of measuring current regulation of PPU and transmitting given configurations through the power-efficient line LPWAN;

- SК-2 are Corrosion Monitoring and Management Units set up into Metering Operation Centers together with ACDS.SK are designed for measuring current-drainage and transmitting given configurations through the power-efficient line LPWAN;

- SК-3 are Corrosion Monitoring and Management Units set up into MOC installation location point and are designed for the process of resistance measuring and transmitting given configurations through the power-efficient line LPWAN. CMU.SК-3 set up into MOC installation location point can be included into CPS-M.SK;

- SK are Power Protection Units which are designed for the process of joint protection of several objects of the Cathode Power Station. They provide the station with current-drainage regulation as well as protect from deleterious effect suppression of neighbouring pipelines and other communications through the process of a protection current device setting and current distribution of the currents sinking into each steel communication in order to achieve demanded protective potential;

- SК is an Alternate Current-Drainage System of the Main Pipelines which is designed for the process of protection from current drainage induced by transmission lines from the protected construction on the ground electrode. It provides the construction with a joint protection of protective potential of the construction as well as decreases dangerous voltage of the system “the pipe-the ground” for a safe process of working for the staff;

- CCD-M.SK is a Current Control Device of the anode ground connection which is designed for protective current control and current distribution from the anode ground connections.

- SК is a permanent Copper Sulfate Reference Electrodes which is designed for using it for carrying out a process of measuring of protective potentials of the communication and ща potentials drop both in the ground and in the electrolyte in the field conditions while defining corrosion resistant protection of the underground metal constructions efficiency;

- LPWAN is an airlock which is designed for making up LPWAN line and which uses a licensed broadband LoRa-modulation allowing to increase transfer capability of the communication line and protection from the interfering signals. The airlock transmits decoded data via the Internet/GPRS/3G/4G/LTE channels from the final device to the central network server. Then they go to the applications server from which the data go to the final user.

A structural scheme of CPS of the System “Atlantic” makes up an Automatization Module (MA) of SICMS.

The Automatization Module (MA) CONSISTS OF THE FOLLOWING EQUPMENT:

- Cathode Protection Stations CPS-M.SK;

- SК-3 set up into MOC installation location point can be a constructive part of CPS-M.SK;

- Metering Operation Centers MOC.SК with Corrosion Monitoring Units CMU.СК и CSRE.SК;

- Metering Operation Centers MOC.SК with Corrosion Monitoring and Management Units CMU.SК, CSRE.SК, PPU.SК.GR-P;

- Metering Operation Centers MOC.SК with Corrosion Monitoring and Management Units CMU.SК-1, CSRE.SК, PPU.SК.GR;

- Alternate Current-Drainage System ACDS.SК provided with Corrosion Monitoring and Management Units CMU.SК-2;

- Metering Operation Centers MOC.SК with Corrosion Monitoring and Management Units CMU.SК-3, MOC;

- other means of CPS (anode beds, power protection units etc.).

SICMS.SK SOFTWARE CONSISTS OF THE FOLLOWING ELEMENTS

- a server part of the system is a server software complex which is responsible for the process of collecting of the information and information storage and the Client’s Software System. The server part operates in a permanent mode providing a permanent process of collecting of the information and the information storage. The server part includes a communication server, a data bases server, an application server and a web-server;

- the client’s server includes the clients’ working positions for the processing and data analysing.

SICMS.SK Server Part consists of:

- CPS Communication server is designed for receiving data from the means of CPS and transmitting configuration instructions and management instructions back. Mobile communication lines GSM/GPRS supported as well as TCP and UDP protocols during the process of data transmitting via power-efficient transmission line LPWAN.

- Data Base Server of CPS is designed for the process of collecting and storage monitoring data taken from technical means of testing and distance control SICMS.SK, measuring and test reports for the process of evaluation of protection process of the pipeline from corrosion.

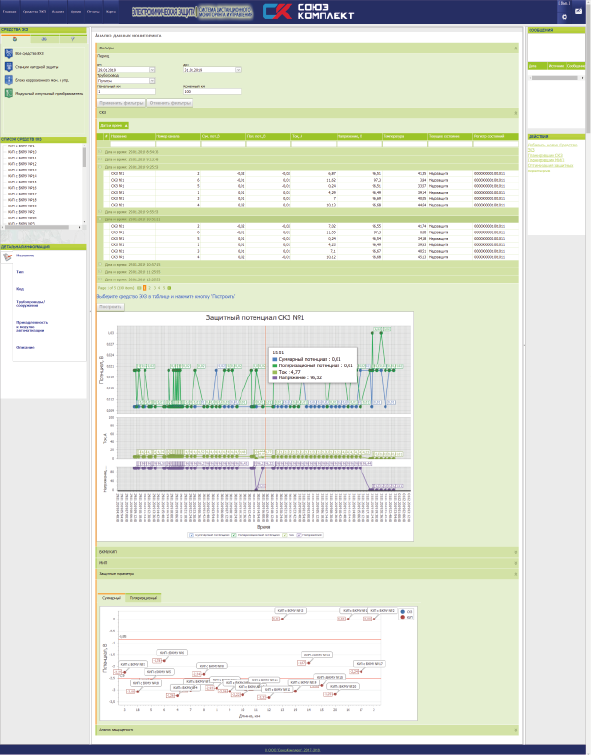

- CPS Web-Server is designed for using the system both in analysis mode and evaluation of protection process of the objects of the pipelines from corrosion one through the internet browser providing a simultaneous access to the information displaying on the web-interface and system functions according to the users’ positions.

- An application server of CPS is designed for carrying out the system of domain logics processing users’ requests and inner module system moments as well as choosing and giving data to the distant users.

These servers can be located in one single-unit server according to the system complication and quantity of the equipment.

The Client’s Part consists of:

- SAW-CPS is a Software Analysis Workstation. It is a combination of the Client’s programmes for an industrial local control which is designed for making the process of collecting, processing, storage and analysis of the information of the protection process of the pipeline from corrosion and set up elements of CPS. It is also designed for providing distance monitoring and the process of protection of the CPS configurations regulation.

- SAW-С –It is a combination of the Client’s programmes provided for supervisor control of the protection of the pipeline process.

The following parts of the system are used as connection system. They are as follows:

- The process of connection between SICMS Server and CPS can be carried out through the Ethernet (transmission connection cable) channels and GPRS/3G/4G/LTE connection channels;

- The process of connection between SICMS and a radio communication airlock can be carried out through the Ethernet (transmission connection cable) channels and GPRS/3G/4G/LTE connection channels. The airlocks LoRaWAN setting up location is the same as CPS.SK setting up location;

- The process of connection between MOC.SK and CMU.SК (CMMU.SК-1, CMU.SК-1, CMU.SК-2, CMU.SК-3) and an airlock LPWAN can be carried out through radio communication lines using LoRaWAN Technology;

- The process of the information exchange online-mode both with SICMS Server as well as the users of SAW-CPS and SAW-С can be carried out through the Internet Channels using authorized access means according to the user position and a given login\password pair.

AS A RESULT OF SMART INTEGRATED CORROION SYSTEM “ATLANTIC” WE ACHIEVED THE FOLLOWING:

- The technological process of CPS support is carried out at a suitable level between “an underprotection process” and “an overprotection process as well as decrease of harmful consequences caused by CPS without telemechanics. So it may be the reason to make operation period of the pipeline at least for 5÷10 years longer as well as decrease emergency situations caused by corrosion.

- The process of permanent technological process regulation of CPS and its permanent provisions both during the technological process stages and its intensification due to MOC monitoring in the pipeline track between neighbouring CPU and in all the corrosion threat areas. This process gives a full image of the process of the pipeline protection and thus increases a real corrosion protection level approximately for 20-30%.

- A complex approach to the process automatization of solving the problems of CPS ( the process of monitoring, the process of protective configurations regulation, the process of the information analysis , the process of evaluation of the protection process, the process of reports arrangement, recommendations etc.) realization which provides its potential growth for 30-40% and thus makes the pipeline system operational period longer. Besides, it decreases the pipeline current repairs charges because of its permanent and efficient protection process as well as increases the quality and taken decisions on CPS management accuracy. Finally, it allows to decrease quantity of man-hours spent on CPS service in track conditions.